This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

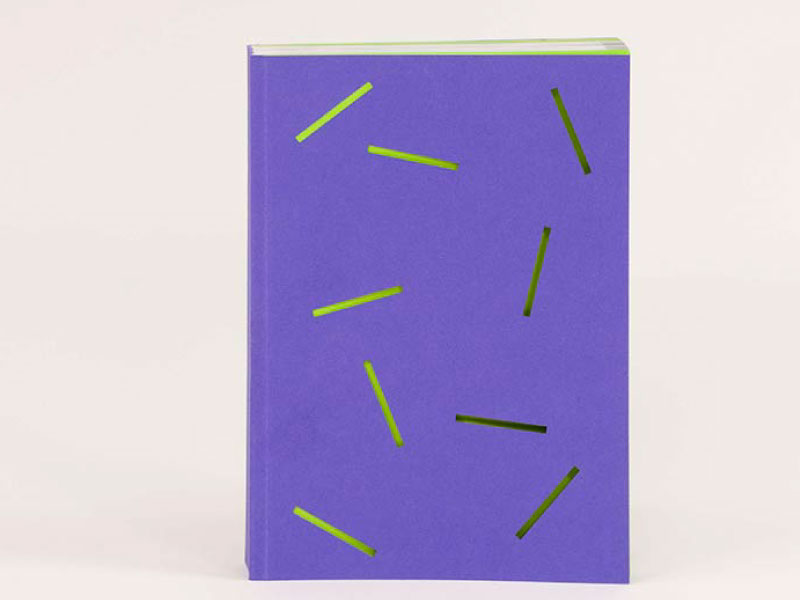

Complex binding, die-cutting

and special finishes

Complex binding,

die-cutting and

special finishes

Complex binding,

die-cutting and

special finishes

Create spectacular effects with special finishes

In any book or publication, the finish is very important to enhance what you want to convey in a more sensory way.

Finishing processes are those that are carried out after printing: binding, folding, die-cutting, stamping, laminating, etc.

There are different ways of binding a book depending on the needs of each project:

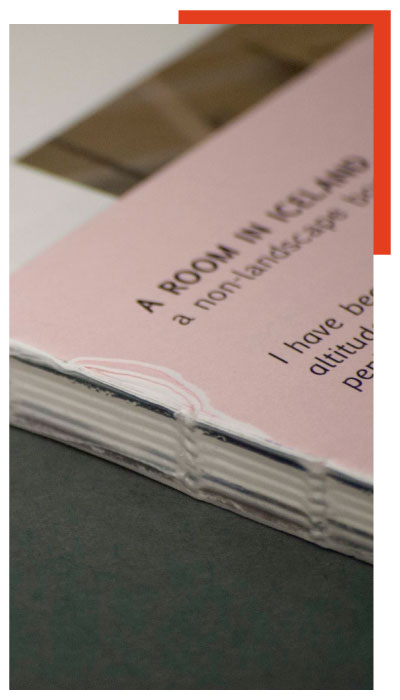

- The most common bindings are: Staple, Wire-O, plastic or metallic spiral, pure paperback, thread-sewn paperback, sewn paperback with hard cover or hardback.

- Less common ones are: Japanese, handmade, thread-sewn, saddle-stitched paperback, Singer stitched, accordion.

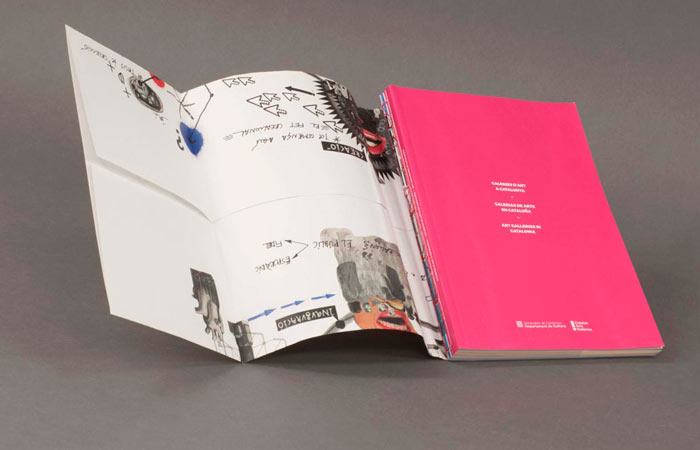

Some books may require special folds (half, accordion, French, Japanese, etc.).

And finally, we can incorporate coatings to increase the durability of the paper or create special textures:

- Varnishes

- Primers

- Barrier coatings

- Laminating with other material (polypropylene, acetate, polyester).

Other finishing operations may include:

- Die-cutting: excellent for creating irregularly shaped end products

- Gluing and indexing: adding tabs to the edges of printed sheets to make it easier to locate information (ideal for product catalogues or textbooks).

CeGe’s specialists can advise you from the very beginning to ensure that the finishing touches give each book that special touch.

CeGe’s specialists can advise you from the very beginning to ensure that the finishing touches give each book that special touch.

Do you want to know more about the type of finishes we offer?

Embossing and debossing

Embossing and stamping are very graphic finishes that can create amazing effects. We offer a variety of embossing services to create imprints on surfaces: conventional, structured, and even embossed. Another way to add depth and volume to your printed materials is embossing: when an image rises above the paper level it is called embossing, whilst when it sinks below the paper level it is called debossing.

Edges

We can gild and tint the edges of a book or catalogue. For gilding we use a film similar to stamping film and for tinting we use anilines to tint the edges.

Die-cutting

We have conventional die-cutting for most jobs. And for those that cannot be made by die-cutting, we use the laser technique that allows us to make literally any type of die-cutting, with no limitations.